AGC Vinythai recognizes the importance of environment management to systematically control, ensure compliance and mitigate the potential impacts.

Environmental management strategies were driven for transparency, sustainable growth, quality, compliance, and benefits to all stakeholders. Besides the compliance with prevention and mitigation measures and conditions stated in the Environmental Impact Assessment (EIA) report and environmental regulator control and legislation; AGC Vinythai has taken additional steps for its processes toward environmental quality.

Environmental Management Systems

AGC Vinythai continues to apply the environmental management approach of ISO 14001:2015, and Eco-Factory framework, also continuously passed the criteria of the Environmental Good Governance (White Flag – Green Star) of the Industrial Estate Authority of Thailand (IEAT). These management approaches support AGC Vinythai and its subsidiary in receiving the ECO-Factory Awards from the Federation of Thai Industries (FTI).

Water Resource Management

The systematic and cost-effective water resources management minimizes the risk of water shortage for production processes.

This management also provides the assessment of risks and maps out the measures to cope with water shortage. AGC Vinythai is a member of the Water User Organization under the Water Resources Act 2018, as well as being a member of the Eastern Water War Room Working Group, which plays a role in cost-effective water resource management to cope with water shortage conditions in order to use the production process of the industrial group and prevent conflicts with the community in the area.

The company also operates a project to recycle wastewater in the production process including a project to install a reverse osmosis system for water recycle.

Air Pollution Management and Control

The management covers the entire range of activities from the selection of high efficiency technology with low emission, operation and maintenance planning, control of air emissions, and the VOC controls and management.

AGC Vinythai implemented the “Air Quality Mobile Monitoring Project”.

The installation of air quality monitoring unit is aimed to identify and monitor the air quality which may impact the employees, and to monitor the boundary air quality for any emergency situations. Moreover, AGC Vinythai has cooperated with the PVC manufacturing industry group in preparation of a project to reduce the concentration of VOCs in the Map Ta Phut area in order to be efficient and conforms to general atmospheric volatile organic compounds standards complying to the announcement of the National Environment Board, No. 30, B.E.2550.

Water Pollution

Under the highest efficient use of natural resources concept of 3Rs, the principle of wastewater treatment begins with reduction of wastewater quantities and segregation of waste right from the beginning. The principle ensures optional use of natural resources and efficient treatment of wastewater by continuously monitoring the COD in water around the clock.

Effluent quality under all parameters was within standards. BOD and COD levels were below 80% of the standard. Wastewater samples are collected and analyzed daily. Wastewater is treated by activated sludge process. Effluence is discharged into Chak Mak public drainage canal.

Industrial Waste Management

The system begins with inventory of all industrial wastes, full control of waste storage, transport, and transfer for safe disposal.

In addition, the company also applied the 3Rs concept to promotion of Circular Economy with the aim to stress cost-effective resources utilization and minimize volumes of waste to be disposed. This initiative not only protects the environment but takes care of our communities’ well-being.

Environmental-friendly Procurement of Products and Service

AGC Vinythai has established a procurement and supply chain management policy to carry out management and procurement of products and services that are high quality, safe, environmentally friendly and reduce pollution with a focus on protecting the environment and natural resources including measures to reduce the amount of waste arising from the production process create an environmental management system and continue to work with continuous improvement as well as to promote and support suppliers and contractors to implement the requirements to promote sustainable environmental management throughout the supply chain.

Energy Conservation

Since the company has high power consumption, according to the Ministry of Energy, the Energy Management was established to monitor and examine energy consumption efficiency in production processes and other activities. Committee members are drawn from each of the main departments at the plant. Its tasks include:

- Long term – Seek initiatives for development and feasible breakthrough projects concerning energy consumption reduction in each area of the manufacturing plant;

- Routine – Closely control, monitor and report on each manufacturing plant. Periodically investigate and audit for Energy Management System compliance.

Enhancement of Logistics by train transportation mode

The salt transportation by train would decrease CO2 emission from truck by using train transportation 70% of salt capacity. CO2 emission can be reduced 8,100 tCO2 /Year

Act on Climate Change

AGC Vinythai is in an energy-intensive industry. The company put utmost efforts to reduce greenhouse gas (GHG) emissions across its entire product lifecycle, from procurement through production, sales, logistics, consumption, and disposal, and contribute towards the realization of a sustainable society. The company issued new integrated Energy Conservation Policy to comply with Ministry of Energy regulation.

Measures to reduce energy consumption

- Plans to achieve annual reductions in energy consumption include:

- 1.) Efficiency-driven

- • Recoating and remembraning the old electrolyzers.

- • Maximize hydrogen consumption at PVC drying unit to reduce natural gas consumption

- • Reduce steam consumption by heat recovery and process optimization

- • Replace new air conditioners on each building

- 2.) Technology Change

- • Steam let down to generate an electricity

- • Change technology of brine treatment

- • Replace new steam trap by venturi technology

Energy Conservation and Reduction of CO2 in the Manufacturing Process

AGC Vinythai has implemented and promoted measures to reduce GHG emissions as follows:

1. Energy usage & GHG emission internal monitoring and control: focus on the Company’s three main utilities following scope 1 (Direct: for natural gas (NG) and scope 2 (Indirect: for electricity and steam);

2. Carbon footprint declaration: focus on GHG emissions. AGC Vinythai received a Carbon Footprint Product (CFP) certificate (all plants) and Carbon Footprint Organization (CFO) Certificate (validation data on 2021) from Thailand Greenhouse Gas Management Organization (TGO).

The company promotes energy conservation activities in production processes that are always linked to GHG emission reduction. These activities include simplifying exhaust gas treatment by converting from heavy oil to natural gas or from natural gas to hydrogen; improving production processes through total oxygen combustion and other techniques; conducting utility-related energy conservation assessments; and starting to install solar panels.

Reduction of Greenhouse Gas Emissions

AGC Vinythai continuously has been putting its effort into various initiatives in energy reduction projects with an aim to reduce GHG emission. Energy management committee provided basic knowledge to employees. After that we gathered the related ideas from brainstorming sessions. All ideas we gained

were screened, investigated, and established in the technical implementation plan following PDCA approach (Plan-Do-Check-Act) which align to GHG emission reduction target in 2030. We have never stopped putting our utmost effort and contribution in using the best solutions for becoming a low-carbon and sustainable business.

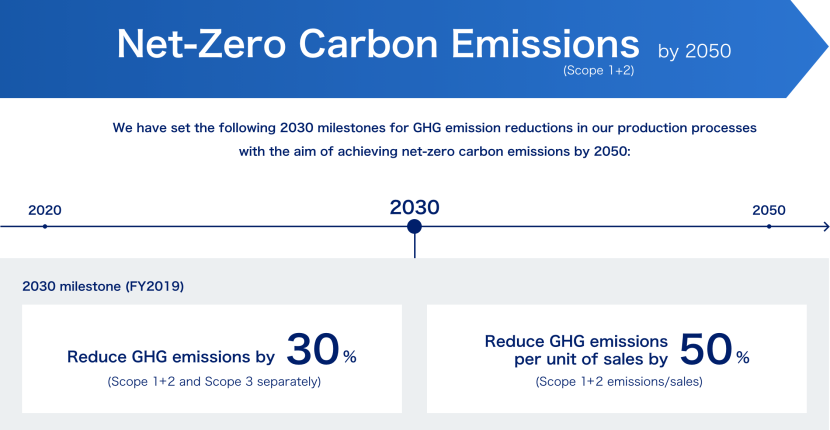

AGC Roadmap

Megatrend - Green Movement Risks

Greenhouse gas emission

In the face of escalating climate change concerns and environmental degradation, the imperative to reduce greenhouse gas (GHG) emissions has become a defining challenge of our time. The Green Movement, with its emphasis on sustainability and eco-conscious practices, has emerged as a guiding force in steering societies, industries, and governments towards a more environmentally responsible future.

Holding a world-scale manufacturing plant, the Company realizes that it is one of the emission sources, and it should be a part of the solutions. Necessary actions taken would help the Company not only in terms of emission reduction, but also in term of natural preservation.

We established the working group to develop Company strategy and initiative in the future. Efficiency-driven, technology change and eco-solution are the focuses being transformed into concrete actions throughout our value chain.

Mitigation:

The Company participates and implements several measures to reduce emissions and to target the development of products that contribute to emission reductions. Those measures are taken with clear objectives in short term and long term, being aligned with our strategic targets relating to energy saving. For examples,

- Efficiency-driven (ME plus and performance management program)

- • Steam optimization in distillation column

- • Improve chiller efficiency

- • Management of hydrogen utilization

- Technology change

- • Solar roof

- • Carbon capture and storage

- Eco-solution

- • Enhance 3Rs For All – Reduce, Reuse, and Recycle

- • Green procurement and low carbon sourcing (Supply chain excellence program)

- Carbon off-set

- Those programs led the Company to receive many Recognition Awards over the past few years.

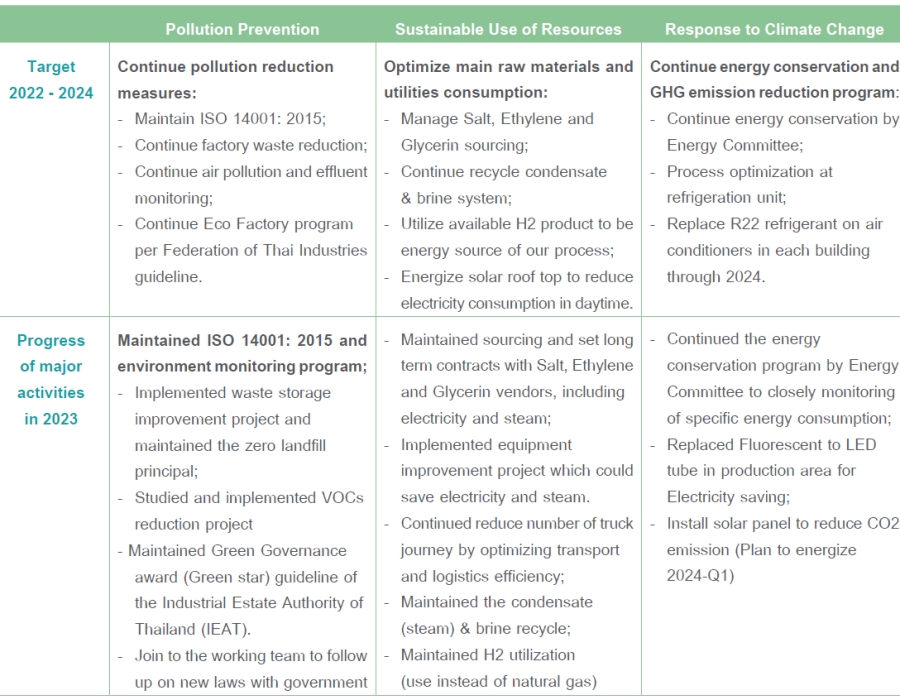

Plan and Progress

Water Resource Management

The systematic and cost-effective water resources management minimizes the risk of water shortage for production processes.

This management also provides the assessment of risks and maps out the measures to cope with water shortage. AGC Vinythai is a member of the Water User Organization under the Water Resources Act 2018, as well as being a member of the Eastern Water War Room Working Group, which plays a role in cost-effective water resource management to cope with water shortage conditions in order to use the production process of the industrial group and prevent conflicts with the community in the area.

The company also operates a project to recycle wastewater in the production process including a project to install a reverse osmosis system for water recycle.

Air Pollution Management and Control

The management covers the entire range of activities from the selection of high efficiency technology with low emission, operation and maintenance planning, control of air emissions, and the VOC controls and management.

AGC Vinythai implemented the “Air Quality Mobile Monitoring Project”.

The installation of air quality monitoring unit is aimed to identify and monitor the air quality which may impact the employees, and to monitor the boundary air quality for any emergency situations. Moreover, AGC Vinythai has cooperated with the PVC manufacturing industry group in preparation of a project to reduce the concentration of VOCs in the Map Ta Phut area in order to be efficient and conforms to general atmospheric volatile organic compounds standards complying to the announcement of the National Environment Board, No. 30, B.E.2550.